PRESSURE SENSORS FOR COMPRESSED AIR SYSTEMS

Pressure is the key point in a compressed air system, as it is actually the pressure which is providing the energy in the form of compressed air to the consumers. In a compressed air system, It is crucial to keep the pressure at a constant and reliable level. Monitoring and measuring the compressed air pressure is needed to save energy, identify degrading at an early stage and keep production machinery running.

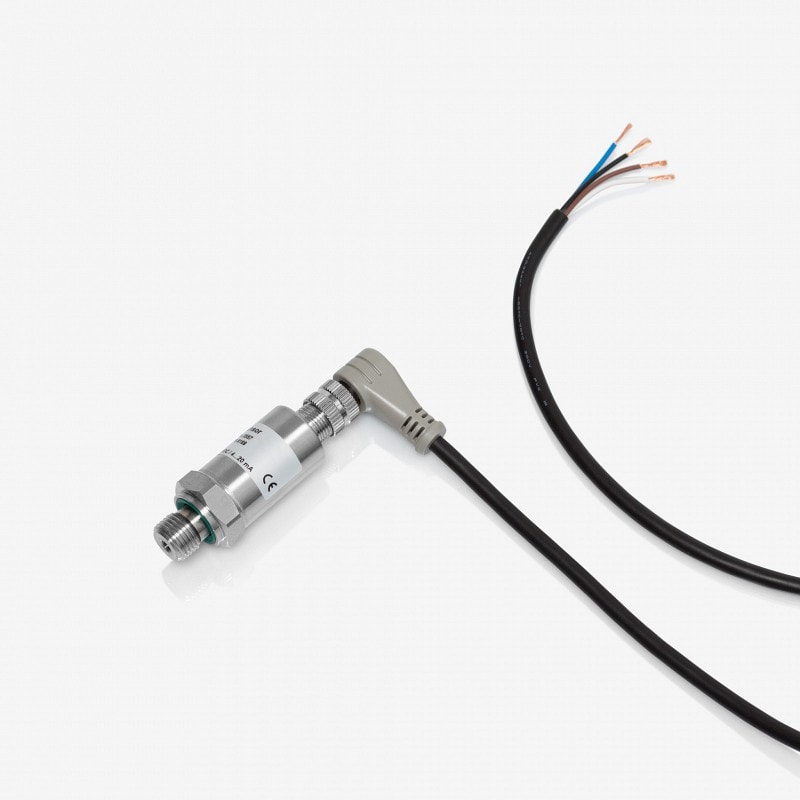

SUTO is offering pressure sensors which fit your needs, with various communication protocols, like analog 4… 20 mA or Modbus/RTU outputs, the pressure sensors are made to seamless integrate into your compressed air monitoring system.

IMPORTANCE OF PRESSURE SENSORS IN COMPRESSED AIR SYSTEMS

Pressure measurement plays an important role in operating an efficient compressed air system. The main task of a compressed air system with all its components is to delivery the needed air flow at a certain pressure level. Only a defined pressure level can reliably supply the compressed air to the points where it is used. Many systems are operated at the wrong pressure levels, keeping the compressed air pressure too high, even when it’s not really necessary. On the other hand, if the pressure drops, machines will not work sufficiently or even stop working.

More information about the importance of pressure sensors for compressed air systems are described in the following section.

At which points in a compressed air system, pressure sensor are used?

Directly after the compressor output, the filtration is placed. First, it’s crucial to measure the pressure after the filtration, because that’s actually the pressure your system will have. But at the same time this can be the first indicator for degrading components. When the pressure drop is too high, the filtration might have a problem or filters are used up.

Finally, the most important pressure measurement is at the point of use. In the end, the machines and processes driven by the compressed air are the system components which will define the pressure needed.

How can a pressure measurement indicate filter life-time and prevent production failings?

Another downside is, that if the filter will be used up more and more, it will create a bigger pressure drop over the time. This will happen until the filter breaks through, suddenly the analog gauge will show a minimal pressure drop. This indicates that the filter is in good conditions, but actually has no function at all. Only with a pressure measurement connected to a data logger or monitoring solution, before and after the filter, users can rely on automatic alarms when the pressure drop gets bigger.

At the same time they can see in the measurement curve, if the filter did break through, as they will see a rising differential pressure which then suddenly drops, a clear indicator of a broken filter.

How can a pressure monitoring ensure a safe and reliable production process?

Only with a constant pressure monitoring and alarm indications, compressed air operators can ensure that machines won’t stop working or productions are not interrupted.

What output signals are available on pressure sensors?

Besides that, SUTO offers state-of-the-art sensors which have a digital Modbus/RTU signal output. The Modbus pressure sensors bring users the advantage, that multiple sensors can be easily connected in a daisy-chain installation, where only one cable is needed to get the data from all connected pressure sensors. This saves installation efforts and lowers the costs.

How are the pressure sensors connected to the compressed air line?

Which gases or medium can be measured with SUTO pressure sensors?

Besides the standard ranges of 0… 16 bar (1.6 MPa) mainly used for compressed air, SUTO offers the pressure sensors also as absolute pressure sensors for vacuum applications, or high pressure sensors to be used in different kind of applications.

Just contact our sales engineers if you need a special range or want to use the pressure sensor in another application.

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We will be happy to help you!