1. April 2019

S120 Oil vapor sensor

In the south China, a renowned LCD manufacturer reached out to SUTO–Their production workers always complained about the air quality of their oil-free compressor with high suspicion on oil contamination. SUTO experts ran an onsite testing for them using the portal S120 oil vapor analyzer. The test result indicated the compressed air did contain oil vapor and showed the precise measurement numbers.

Tracking down this clue, SUTO exports made a thorough investigation, and finally found the reason: The compressor room was too near to the kitchen. This manufacturer took SUTO’s advice moving the kitchen away, and the problem got resolved. S120’s reliability, accuracy, portability as well as SUTO experts professional service won trust of this manufacturer. Later they bought an S120 from SUTO.

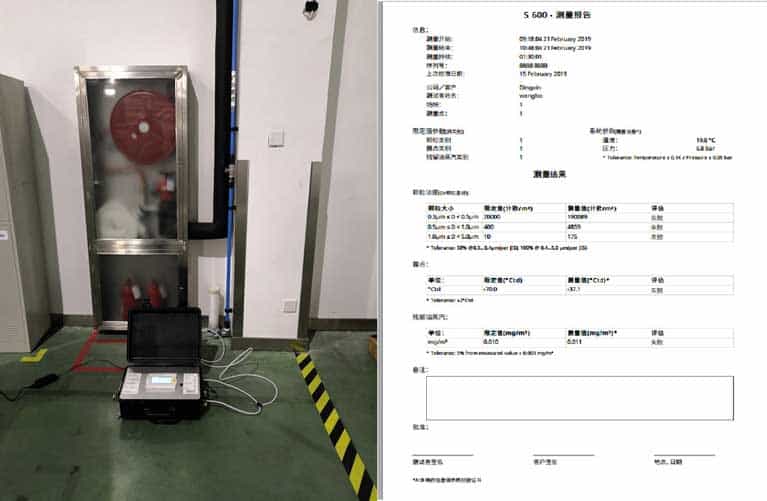

S600 Compressed air quality analyzer

In the north China, an electricity customer consulted SUTO on their bad compressed air quality that persisted for a long time. Although they have added filters and dryers based on their experience, it gained little effect.

SUTO experts carried the S600 portable air quality analyzer to the site, and started the measurement. At the end of the measurement, S600 generated a comprehensive report on the compressed air quality. Based on this report, this customer carried out a targeted renovation on the compressor environment, and received a satisfied result.