MONITORING SOFTWARE FOR COMPRESSED AIR SYSTEMS

To manage a compressed air system and making it more efficient, a software solution is needed and mandatory. The application software should not only log the data, but must also offering a live monitoring, alarm management and reporting functions as crucial parts of the software solution.

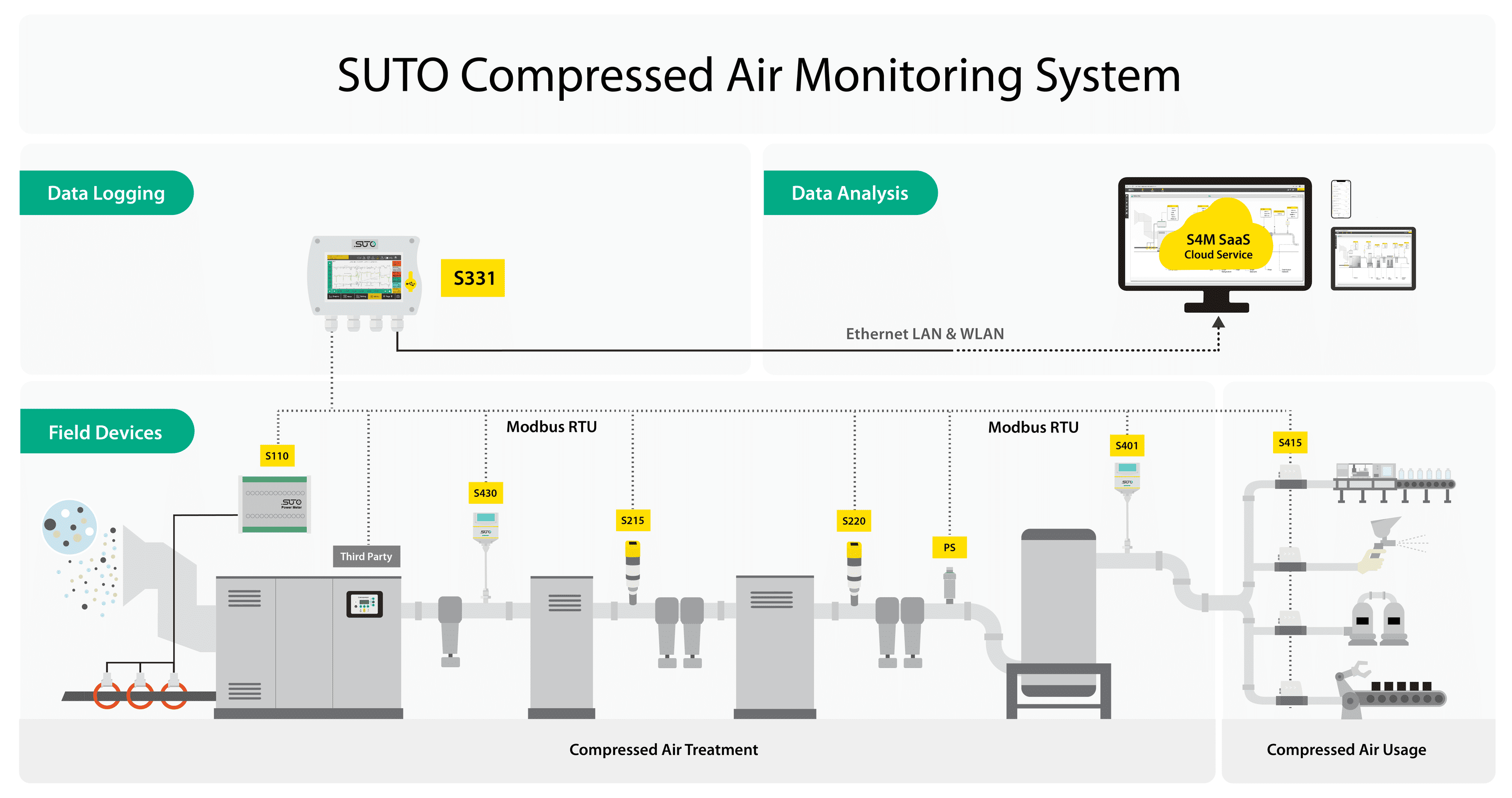

SUTO Software is optimized for compressed air systems, users can not only profit from the useful tools provided, but also experience a seamless integration of the measurement hardware into the software. At SUTO, both, the software and hardware, is in house development by our experienced and passionate engineering teams. This provides users the best experience, an easy setup and plug & play solutions.

THE IMPORTANCE OF COMPRESSED AIR MONITORING SOFTWARE

Reducing compressed air costs and optimizing compressed air systems is only possible with the right monitoring software

When field instruments are installed to measure and monitor compressed air systems, they provide useful data for operators. Nowadays, this data is often not utilized throughout its possibilities. Sensor measurement data, like actual flow readings, total air consumption or compressor electrical power measurements, are read from local displays and manually transferred into spreadsheets for reporting purposes.But the filed data contains so much more information, which is the base for every process optimization. Graphical analyzes of measurement data helps operators to easily find irregularities in the compressed air system. But also simple tasks like reporting the total air consumption by building, production line or precess can be realized by the right monitoring software solution in a single click. Only by comparing logged measurement data with KPIs (Key performance indicators) can help to reduce costs and help to understand the compressed air system.

SUTO monitoring software is flexible, optimized for compressed air system and provide a wide variety of functionalities built in.

Why is software playing such an important role when it comes to compressed air monitoring?

SUTO software is capable to analyze big data sets, create useful graphic views or provides real time values of each single sensor. Bigger systems can be grouped into smaller locations, so all values can be easily seen in a single screen. But not only live values are important, especially the past data is crucial for optimizing compressed air system, going back in time and recognize changes on the system, finding degrading components or other irregularities.

Which sensor types can be connected to SUTO software solutions?

For this, SUTO software support Modbus/RTU and Modbus/TCP protocols to collect the data from any compressed air measurement solution. Furthermore, via gateways, its even possible to integrate any industrial protocol into the system.

Why are SUTO solutions cloud based or running in a web browser?

Cloud solutions are offering users the next level of freedom, the software just works without additional efforts. Since the software is accessed via a web browser, it offers the most flexibility. Users can access the software from any PC and operating system, no matter if it’s a Windows PC, an Apple Mac or even a Linux system.

SUTO software solutions are taking compressed air measurements to the next level by offering IoT solutions paired with the right application software. Welcome to the Industry 4.0.

What kind of software solutions can SUTO offer?

SUTO offers software for live monitoring of the compressed air system, providing a real time data, alarm management and reporting functions.

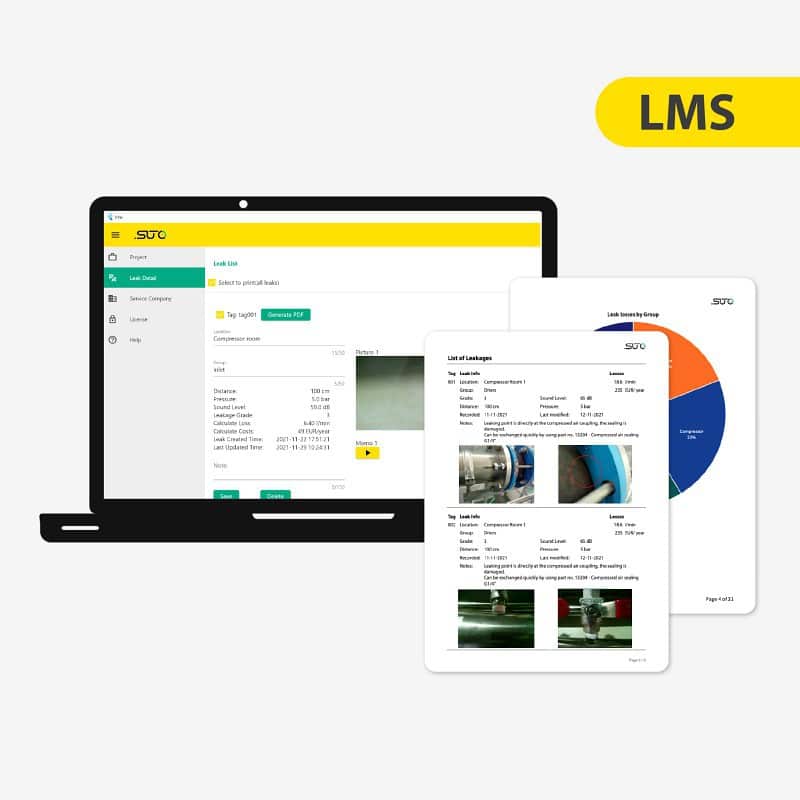

Additionally, SUTO offers software to manage leak surveys, but not only managing the found leaks, it provides service companies the possibilities to manage the complete audit, from finding the leaks, collecting the data and creating reports, to finally fixing the leakages, estimating cost savings and repair costs.

In addition, software tools for quick analyzes and data logger read-outs are offered for free.

Which software is used to configure SUTO sensors in the field?

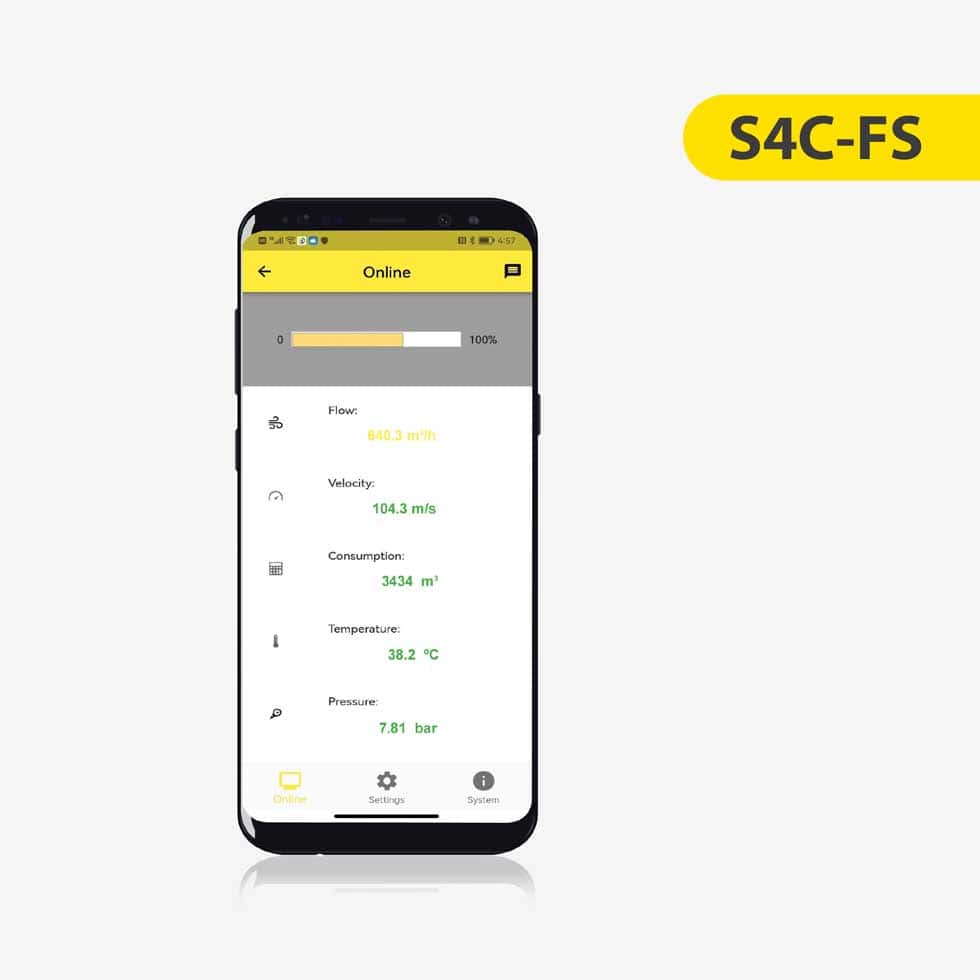

SUTO solved that by offering wireless solutions directly integrated into the sensor, paired with dedicated smartphone applications.

Now, technicians and engineers can connect to sensors and measurement equipment wirelessly and from a distance. The application shows the real-time measurement data and allow users to configure the sensors easily. Parameters like pipe diameters, communication parameters or analog output scaling can be done easily from the smartphone with a single click.

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We will be happy to help you!