FLOW METERS FOR COMPRESSED AIR AND GASES

Flow and consumption measurement of compressed air and gas is an important task in the manufacturing industry in order to optimize energy efficiency and save costs.

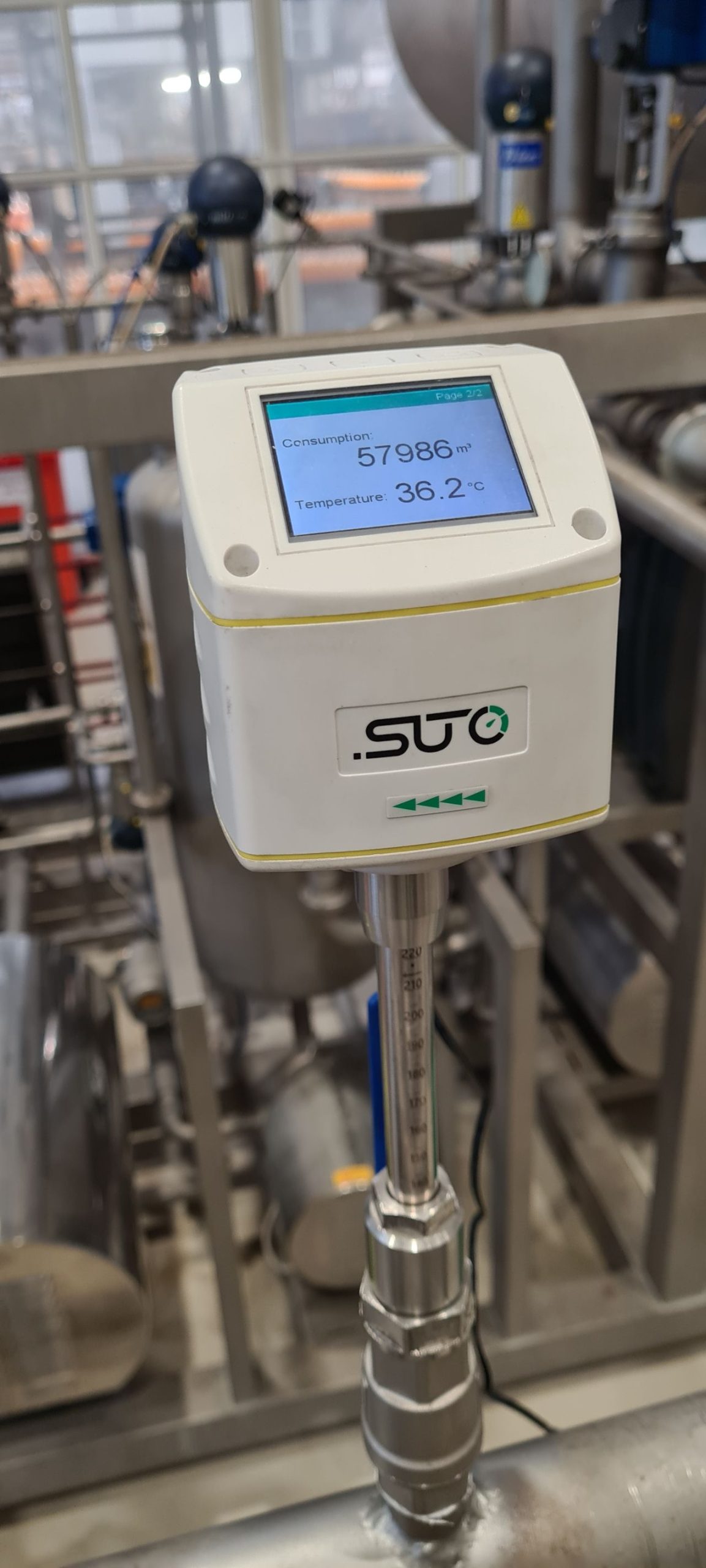

SUTO iTEC flow meters for compressed air and gases provide accurate and reliable flow and consumption measurement and come with various signal interface options (4-20 mA analog, pulse, Modbus/RTU, Modbus/TCP, M-Bus, HART).

IMPORTANCE OF COMPRESSED AIR AND GAS FLOW MEASUREMENT

Almost any industrial process uses compressed air as one of its energy resources. Compressed air is easily accessible and available throughout the factories and plants as a reliable energy form. But where it is normal to measure electrical power consumption, it is often found that compressed air as an energy source is not measured and monitored. A constant and reliable compressed air flow at any point in the network is necessary to keep the process under control.

Measuring the compressed air flow gives the control back to the operators, knowing how much air is consumed during which period of productions and how much air is actually needed.

Overall flow meters for compressed air and gas from SUTO iTEC are offering operators to get an overview of their compressed air performance and getting it under control.

Why measuring compressed air flow and consumption?

Compressed air is one of the most expensive energy forms and widely used in almost any application and process. Only by measuring the compressed air consumption with thermal mass flow meters or pitot-tube flow meters, operators of compressed air system are enabled to optimize the system, operating their compressors at the highest efficiency and save costs.

But not only saving costs, an optimized system also saves energy and reduces the carbon footprint of a factory or plant.

What types of flow meters for compressed air and gases are available?

Flow meters are available as Insertion type models, which can be installed under pressure through a ball valve or as inline types, where the flow meter is provided with a measuring section. SUTO is using two different types of flow meters for compressed air and gases to provide measurement solutions for different applications:

- The thermal mass flow meters are suited for dry and clean conditions and can be used in compressed air or any other gas.

- Pitot-tube flow meters allow the measurement of wet air as it exists at compressor outlets, thus enabling the performance measurement of compressors.

Special OEM versions of the thermal mass, as well as the pitot-tube flow meters, are available for compressor/dryer makers and Energy Management Solution providers (IIoT) as very economical flow meter solutions.

How do compressed air flow meters help operators?

The installation of compressed air flow meters empowers operators to address inquiries such as:

- How much air does each machine need?

- Does my compressor deliver the air required?

- Are the compressors operating efficiently?

- Are there losses in the compressed air system during periods where production is stopped?

- How much money is spent on compressed air?

Overall flow and consumption measurements offer operators an overview of their compressed air performance and how to get it under control.

Talk to our experts to help you find the most suitable solution for your question and application

In which applications are flow and consumption meters used?

Typically, compressed air flow meters are used in the main header pipes of a compressed air system. By doing so, the total consumption as well as the consumption of single production lines can be easily monitored. But also, the measurement of single consumers is an important point, especially when operating costs play a vital role.

Besides that, gas flow measurements, like oxygen flow rates and consumption in medical applications, are to be monitored and controlled. The flexibility of SUTO flow meters offers users the best suitable measurement technology in almost any application.

The main applications for compressed air flow meters are:

- Compressor Efficiency Test

- Allocate compressed air costs in your system

- Identify Leak losses when system is not used

- Identify high consumers in your system (costs point)

- Identify high consumers in your system (Equipment health, as a broken machine might consume more air)

- System Performance to identify weaknesses of the system (demand peaks, not enough flow available, etc.)

- Planning compressed air capacity by knowing the demand (to know what’s actually needed to size the compressor, tanks, etc.)

How to choose the right compressed air flow meter for your requirements and needs?

To choose the right flow meter for compressed air and gases, it is needed to know the on-site conditions, such as:

- Is the air or gas dry or wet?

- What is the pipe diameter at which flow and consumption should be measured?

- What flow rates are expected?

- Should the flow meter be inserted under pressure?

- Is there enough straight inlet section available?

- What output signals / interfaces are needed?

At SUTO iTEC, our experts are always ready to help. With a track record of successfully matching customer needs and applications, we have yet to meet a case where we couldn’t find the perfect flowmeter solution.

Which gases can be measured by SUTO iTEC flow meter products?

SUTO flow meters are not only suited to measure compressed air consumption but can also measure almost any gas that is typically used in industries.

Thanks to the thermal mass technology and pitot-tube technology, it’s not needed to compensate the temperature or pressure, no matter which gas flow meters are used. For the standard industrial gases, SUTO can provide real gas calibrations when needed.

Typical gases besides compressed air are: Nitrogen (N2), Oxygen (O2), Carbon dioxide (CO2), Argon (Ar), Natural Gas, Helium (He), Hydrogen (H2), Methane (CH4) and many more.

The SUTO flow meters for compressed air and gases are suited to measure almost any pure gas, but also gas mixtures, please contact our support if you need custom solutions to measure the process gas as you need it.

What measurement technology is used in SUTO flow and consumption meters?

SUTO flow meters for compressed air and gas are based on two technologies:

- Thermal mass flow meters for dry air and gases: With SUTO iTEC thermal mass flow sensors, users are enabled to measure the mass flow, volumetric flow and consumption of any gas. Thermal mass flow sensors provide the advantage of wide measuring ranges and high accuracy.

Besides that, thermal mass flow sensors are long-term stable, easy to maintain and can be installed in existing pipe systems, making them a universal product for a wide variety of applications. - Pitot-tube flow meters for wet air and gas applications: When it comes to measuring the compressed air directly at the outlet of the compressor, where the air is unfiltered, hot and wet, a thermal mass flow sensor cannot be used.

For this application, SUTO iTEC is offering wet air flow meters based on the pitot-tube principle. This insertion-type sensor uses the differential pressure that is created at the sensor tip (pitot-tube), paired with a temperature and pressure measurement, to measure the volumetric flow of the wet air.

With this sensor, it’s possible to measure the FAD (Free air delivery) as well as the total flow of the compressed air. The pitot-tube flow meter is the right tool for energy audits and often used for compressor performance tests as well.

Why are thermal mass flow meters also suited for Oxygen, CO2 and Nitrogen?

Every gas has a specific gas constant, which indicates the thermal characteristics of the gas. Thermal mass flow meter technology is based on this constant, enabling the flow meter to be used in this industrial gases, even if the flow meter is calibrated and set to air.

The technology allows users of the mass flowmeters to switch the gas type via a software setting directly on the sensor using the local display or a smartphone with a wireless connection. With this, a compressed air flow meter can be turned into an oxygen flow meter or nitrogen flow meter at a glance.

Still, thanks to the thermal mass flow principle, there is no need to compensate for pressure or temperature additionally. Therefore, flow meters are perfectly suited to be used in many gas applications.

Do SUTO flow meter require an additional temperature or pressure compensation?

Traditional flow meters, like rotary flow meters, are often used in many applications. But their major drawbacks are the moving parts, which need regular maintenance, their high installation costs and the need for additional temperature and pressure compensation.

SUTO iTEC thermal mass flowmeters do not need any additional pressure or temperature compensation. The technology used is pressure-independent. The absolute gas temperature is measured by the sensor and is already included in the measuring principle. Therefore, additional temperature compensation is not needed.

SUTO iTEC pitot-tube flow meters already come with an integrated temperature and pressure measurement, which is used to calculate and measure the volume flow of compressed air and gases. Additional sensors for compensation are not needed.

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We will be happy to help you!