COMPRESSED AIR QUALITY AND PURITY INSTRUMENTS

Ensuring the compressed air quality according to ISO 8573-1 is one of the most important points when it comes to high-quality production processes. But not only in food and beverage, also in other industrial applications it is important to know the oil contents, the particle concentration and the humidity levels of the compressed air supplied at the point-of-use. Typical air quality audits in regard to the ISO 8573-1 can be time-consuming and costly, it is time to change that.

SUTO is providing cost-effective solutions, which provide real-time measurements on site to make sure the process is always under control, preventing failures and reducing risks drastically.

IMPORTANCE OF COMPRESSED AIR QUALITY TESTING AND ISO 8573-1 REQUIREMENTS

In modern compressed air systems, compressed air quality is an important factor when it comes to process reliability and safety. Compressors draw in all kinds of contaminants at their inlets, which are then transported into the system. Filters are usually installed after compressors to filter out these contents. The three parameters to be monitored are:

- Oil content (measured in weight per volume [mg/m3])

- Particle concentration (measured in counts per cubic meter [cn/m3])

- Water concentration (measured as dew point temperature [°C Td])

Choosing the appropriate compressed air quality testing equipment is the first step to adequate measurement of compressed air quality according to ISO 8573-1.

Continue for more information and important questions about compressed air quality testing according to ISO 8573-1.

Why is compressed air quality a crucial parameter in a compressed air system?

Compressed air is used in almost every industrial process, from food and beverage to medical applications. Sometimes the compressed air is in direct contact with the products, for example in packaging processes where packaging containers are blown out with compressed air.

Considering that the compressed air system is part of the process and can be in direct contact with the products, it is very important to monitor the air quality. ISO 8573-1 has defined quality classes for the 3 main parameters, such as oil content, particle concentration and pressure dew point (water concentration), which help users define the air quality that may come into contact with the final product according to defined standards.

Modern filtration systems are capable of filtering out any unwanted contamination from the compressed air used, most likely introduced by the compressors. However, in the event of filter failure or degradation, operators must have reliable real-time monitoring to respond to these failures, otherwise production output may be contaminated or even recalled from consumers.

In such cases, the damage to the product, but also to the brand reputation, can be enormous. Only continuous monitoring of compressed air quality can prevent this.

Where are compressed air impurities typically are coming from?

A modern compressed air system consists of a compressor followed by filters and air dryers, a so-called filtration system. These filters are needed because compressors draw in ambient air and introduce any contaminants from the ambient air into the system.

Contaminants in a compressed air system can come from a variety of sources and affect the compressed air quality and purity, including

1. Air Intake

Air drawn in from the environment and compressed can contain dust, particles and other contaminants. Water from the ambient air is also drawn in, compressed and introduced into the system.

2. Compressor

The compressor itself can produce contamination such as oil mist, carbon particles and other contaminants. Even an oil-free compressor can therefore introduce oil into the system, as oil vapor may already be part of the intake air.

3. Piping and Fittings

If the compressed air system is not properly maintained, rust, scale and other deposits can build up in the pipework and fittings, contributing to air contamination. Valves, seals, fittings, quick disconnects or other components are often sources of contamination.

4. Dryers and Filters

If the compressed air system includes equipment such as filters and dryers that is not properly maintained, they can become clogged and no longer effectively remove contaminants from the air.

5. Air Leaks

Leaks in the system can allow outside air and contaminants to enter the compressed air lines.

Monitoring compressed air quality with the correct compressed air analyzers is essential to detect all possible contaminants.

Why is real-time compressed air quality testing so important?

In the past, a common approach to assessing compressed air quality was to take air samples on site and analyze them in external laboratories for quality audits. However, there was a significant drawback to this method: results took weeks to become available, preventing real-time monitoring of compressed air quality.

As a result, relying on probe sampling and external laboratory analysis provided only a snapshot of air quality at a specific date and time. Any degradation or filter failure that occurred between audits could go undetected by operators.

SUTO systems offer live on-site monitoring solutions that provide real-time measurement of compressed air quality. This capability enables operators to react immediately when problems occur.

With real-time measurement of compressed air quality, operators can address changes as they occur and prevent potential consequences before they escalate. By using SUTO’s monitoring solutions, operators can take proactive steps to maintain optimal compressed air quality and ensure uninterrupted operations.

Our team of experts can assist you in providing the best solution for your application

ISO 8573-1: How Does It Define Compressed Air Purity?

ISO 8573-1 is an international standard that specifies the purity of compressed air with respect to three main contaminants: particles, water and oil. These contaminants are classified into different purity classes based on their concentration levels, providing guidelines for assessing and maintaining the quality of compressed air in various industrial applications.

Here’s a brief overview of the three main contaminants and their respective purity classes according to ISO 8573-1:

Particles: This refers to solid particles present in compressed air, such as dust, dirt and rust. ISO 8573-1 defines different particle size ranges and corresponding concentration levels for different cleanliness classes, ranging from Class 0 (no particles allowed) to Class 9 (maximum allowable particle concentration).

Water: Water vapor in compressed air can cause corrosion, damage to pneumatic equipment and contamination of products. ISO 8573-1 specifies the pressure dew point (PDP) as a measure of water vapor concentration, with purity classes ranging from Class 0 (dry air, no water vapor) to Class 9 (maximum allowable PDP).

Oil: Oil vapor and liquid oil in compressed air can adversely affect pneumatic equipment, contaminate products and create safety hazards. ISO 8573-1 categorizes oil contamination based on both vapor and liquid oil content, with purity classes ranging from Class 0 (no oil allowed) to Class 9 (maximum allowable oil concentration).

By adhering to the purity classes outlined in ISO 8573-1, industries can ensure that their compressed air systems meet the quality standards required for specific applications, thereby minimizing risk and maintaining operational efficiency.

What is the meaning of the ISO 8573-1 compressed air quality classes?

The purpose of ISO 8573-1 Compressed Air Quality Classes is to provide guidelines for classifying contaminants in compressed air. This standard defines contamination limits for three parameters: oil, particles and water, represented in classes typically ranging from 1 to 5 or 6.

Each parameter is considered as a single reading, allowing systems to have different ISO 8573 classes for different parameters. For example, a classification of 1.2.1 means that the particle concentration is in class 1, the dew point is in class 2 and the oil concentration is in class 1.

Particle concentration measurement is divided into three channels based on particle size, each with its defined limits according to ISO 8573-1: 0.1 < d ≤ 0.5 µm; 0.5 < d ≤ 1.0 µm; 1.0 < d ≤ 5.0 µm.

Water or moisture concentration is expressed as pressure dew point, which indicates the level of moisture in the compressed air, while oil concentration is measured in milligrams per cubic meter (mg/m³) of air.

In essence, ISO 8573-1 assists compressed air system operators in defining air quality and provides common references and limits for easy classification of systems.

| Class | Particle Concentration | Pressure Dew Point | Oil Concentration | ||

|---|---|---|---|---|---|

| cn/m3 | ºC (ºF) | mg/m3 | |||

| 0.1 < d ≤ 0.5 µm | 0.5 < d ≤ 1.0 µm | 1.0 < d ≤ 5.0 µm | |||

| 0 | As specified by the equipment user or supplier and more stringent than class 1 | ||||

| 1 | ≤ 20,000 | ≤ 400 | ≤ 10 | ≤ -70 (94.0) | ≤ 0.01 |

| 2 | ≤ 400,000 | ≤ 6,000 | ≤ 100 | ≤ -40 (-40.0) | ≤ 0.1 |

| 3 | undetermined | ≤ 90,000 | ≤ 1,000 | ≤ -20 (-4.0) | ≤ 1 |

| 4 | undetermined | undetermined | ≤ 10,000 | ≤ +3 (+37.4) | ≤ 5 |

| 5 | undetermined | undetermined | ≤ 100,000 | ≤ +7 (+45.6) | > 5 |

| 6 | x | x | x | ≤ +10 (+50.0) | x |

How to ensure compressed air quality according to ISO 8573-1?

Ensuring compressed air quality in accordance with ISO 8573-1 involves several key steps. Firstly, operators must understand the guidance provided by ISO 8573-1, which classifies compressed air quality into different classes.

A crucial aspect for operators is the selection of appropriate measurement tools that can operate under pressure. Traditionally, accurate results have required on-site sampling followed by external laboratory analysis. However, this method is expensive, complex and time-consuming. It also often involves disruptions to operations and system changes. In addition, operators are unable to respond immediately to changes in the field because they have to wait for lab results.

SUTO addresses these challenges by offering live monitoring solutions for compressed air quality measurements in accordance with ISO 8573-1. These advanced instruments, like the all-in-one S600 and S601, provide real-time on-site readings, are easily installed under pressure and allow users to respond immediately to changes in the compressor system. This not only saves customers on audit investment, but also prevents production downtime and ensures a highly reliable process.

Which measurement principles are used in SUTO oil vapor sensor and particle counters?

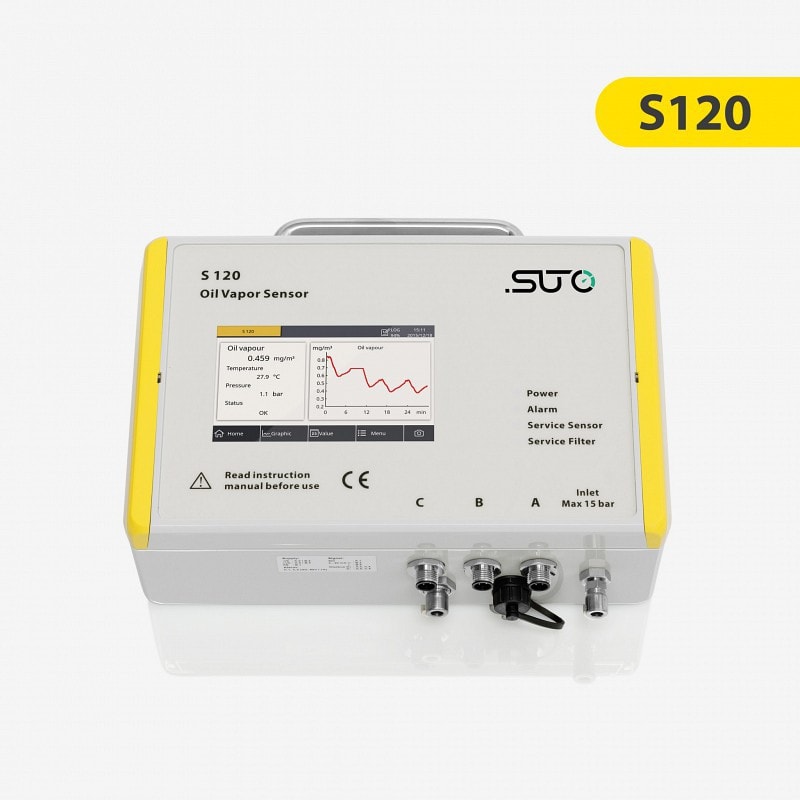

SUTO utilizes PID (Photo Ionization Detectors) sensors in products like the S120, S600, and others to measure oil vapor in compressed air systems. PID sensors function by using UV lamps to ionize hydrocarbon molecules in the air passing by the sensor element. This ionization causes a change in the electrical charge of the molecule, which the sensor detects and quantifies to determine the concentration of hydrocarbons in the air. As oil vapor measurement is mandatory according to ISO 8573-1 for assessing oil contamination in compressed air systems, PID sensors represent the cutting-edge technology for real-time oil measurement.

Additionally, SUTO particle counters are equipped with laser optical sensors. These sensors work by emitting a highly efficient laser beam across the air stream. When an airborne particle passes through the laser beam, it scatters the light, which is detected by a light-sensitive sensor. By analyzing the scattering patterns of different particle sizes, the sensor not only quantifies the number of particles but also identifies their size range. This capability enables compliance with ISO 8573-1 and ISO 8573-4 standards for particle contamination in compressed air systems.

Contact our expert team for more information.

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We will be happy to help you!