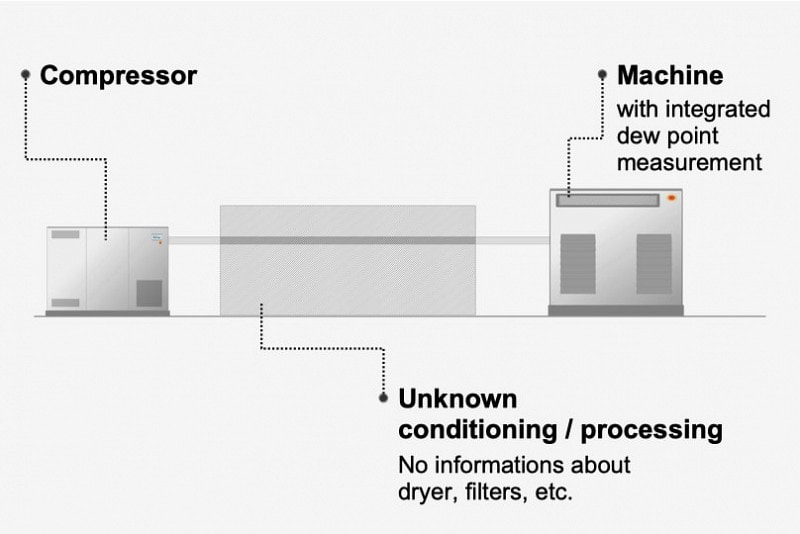

Manufacturers of machines do not supply the compressed air within the machines, and the clients are responsible for the compressed air and have to maintain the air quality. But many companies do not recognize the compressed air quality as an important factor, so they use the machines without supplying high-quality compressed air.

A SUTO client, manufacturing grinding machines, took one step ahead by integrating the dew point measurement directly into their machines. Paired with a data logger, this solution offers clients the control over the supplied air. Furthermore, this solution uses the integrated display to switch relays based on defined limit values. This helped the manufacturer get back the control of the compressed air and keep the production process at the highest level.

A simple dew point sensor can help improve the process quality and help your brand to be recognized as a quality manufacturer.