CASE STUDY

Ensuring High Compressed Air Quality Standards Through Oil Vapor Monitoring

In the cosmetic manufacturing industry

Application

Compressed air quality audit with S120 Oil Vapor Monitor

Goal

Meeting higher compressed air quality standards and ensuring product quality

Customer

Cosmetic Industry

Sector

Manufacturer of cosmetic skin care products

Overview

In the ever-evolving cosmetic industry, maintaining high-quality production standards is crucial. A leading Cosmetic Company, facing challenges related to compressed air quality. They consulted the expertise of Airtec Global, a service provider of SUTO iTEC, to conduct a comprehensive air quality audit utilizing the SUTO S120 Oil Vapor Monitor.

New Regulations Regarding The Air Quality

The cosmetic company had been utilizing the same lubricated air compressor system for over 20 years without adequate filtration. With the introduction of new regulations mandating higher compressed air quality standards to prevent contaminants on the containers of their skincare products, the company recognized the need for a thorough assessment and upgrade of their compressed air system.

Initial Assessment: High Levels of Oil Vapor

Upon conducting the compressed air quality audit by Airtec Global using the S120 Oil Vapor Monitor, the readings revealed alarmingly high levels of oil vapors in the compressed air.

The prolonged use of the existing compressor system without proper filtration had led to the accumulation of contaminants, jeopardizing the quality of the cosmetic products.

Testing at the Point-of-use

SUTO iTEC’s partner, Airtec Global, collaborated to address the issue comprehensively. The initial step involved recommending the integration of an activated carbon filter and coalescing filter into the existing system. While these modifications resulted in a noticeable improvement, the readings still did not meet the newly established, stringent air quality standards.

Upon closer inspection with the S120, it was discovered that the accumulated contaminants in the piping distribution system were contributing to the persistently high readings. Recognizing the need for a more targeted approach, additional point-of-use filtration, specifically oil mist removal filters, was recommended. This strategic addition significantly contributed to bringing down the readings to the desired range, ensuring compliance with the stringent regulations.

Role of S120 in Success

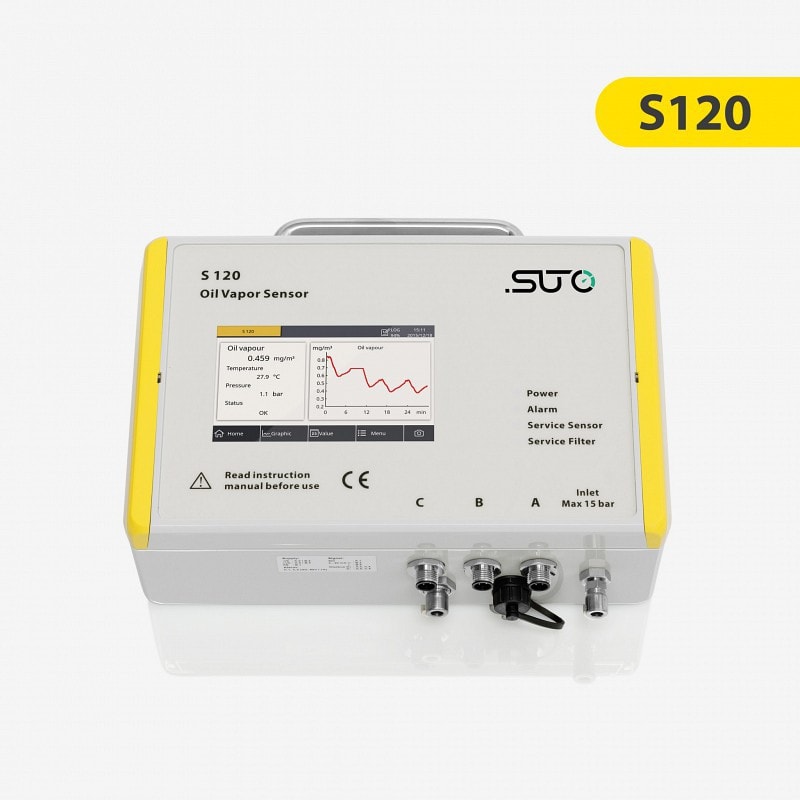

The S120 Oil Vapor Monitor played a crucial role in achieving a higher compressed air quality standard. The precise readings provided invaluable insights, guiding the step-by-step implementation of solutions.

Without the accurate data from the S120, identifying the specific areas of concern and tailoring the solutions to address them would have been a challenging task.

Results and Conclusion

The cosmetic company, Airtec, and SUTO iTEC worked together to successfully transform the compressed air system. The cosmetic company met and exceeded regulatory standards for air quality by implementing targeted filtration solutions, addressing the underlying causes of contamination, and relying on the S120’s accurate readings.

This case study highlights the importance of regular air quality assessments, especially in industries with evolving standards. The proactive approach taken by the cosmetic company, coupled with the expertise of SUTO iTEC and its partners, not only ensured compliance with regulations but also enhanced the overall quality and purity of the cosmetic products, safeguarding the company’s reputation and customer satisfaction.

Partner

Airtec Global is a leading industrial compressed air services and solutions provider in North America.

Products in Use

Personal Advice

Would you like to receive more information about products and applications? Or do you need personal advice? We will be happy to help you!