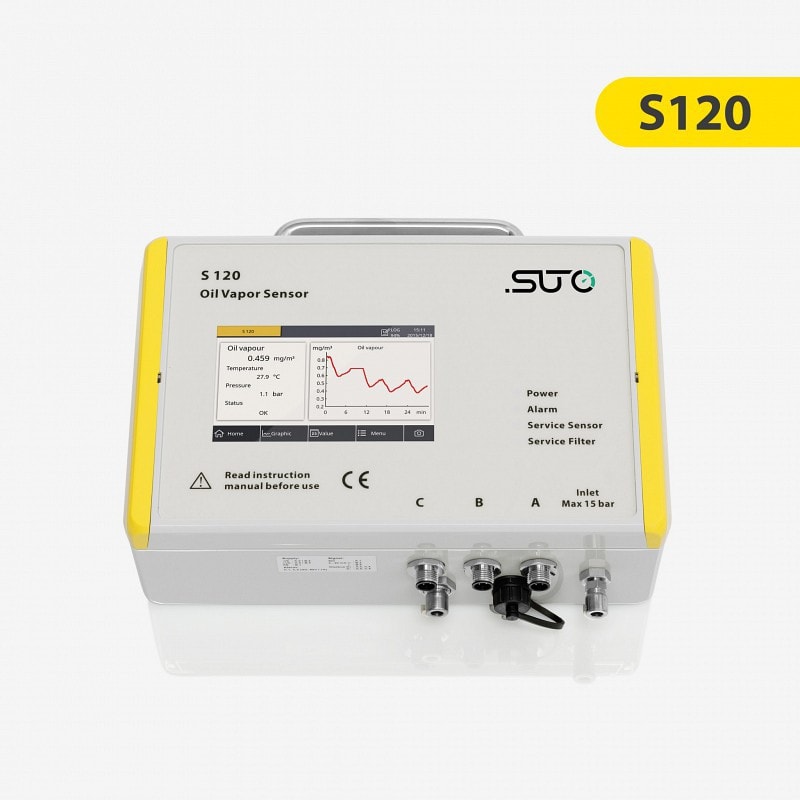

S120

S120 Oil Vapor Monitor for Compressed Air Purity Measurement

Precise measurement of oil contents in compressed air and gases, permanently or for spot checks.

Plug & Play oil vapor monitoring solution

Optional integrated 5” touch screen display

Oil vapor measurement in a range of 0.001 to 5.000 mg/m3

Integrated data Logger for online monitoring and printing

Latest PID sensor technology for fast response time

Integrated dew point sensor option: -100 ... +20 °C Td

Various connection options for software and BMS

For Compressed Air, Nitrogen N₂, Carbon dioxide CO₂

The S120 Oil Vapor Sensor monitors oil vapor contents of compressed air and gases permanently or for spot checks when used as a portable unit with the S551 Portable Data Logger.

With simple installation and the outstanding performance of the S120 it makes it the ideal choice when residual oil vapor contents need to be measured. The built-in PID sensor provides highest accuracy for reliable oil vapor monitoring.

Ensure Your Compressed Air Quality

Oil free compressed air is not an easy task to be achieved. Monitoring oil vapor content is a must in many industries and applications to avoid contamination in products and risk to health of humans. The S120 makes monitoring oil vapor in a range of 0.001 to 5.000 mg/m3 affordable and reliable. Just connect your compressed air system through sampling hose and quick-connector.

Display Option and Various Output Signals

The optional integrated 5” touch screen display with data logger function help to easily view and store data.

Various output signals, such as 4 … 20 mA (isolated); Modbus/RTU (RS485); Modbus/TCP (Ethernet) and USB, can be used to easily connect the S120 Oil Vapor Monitor to SUTO Data Loggers and Displays or central building management systems.

Integrated Automatic Calibration

The integrated automatic calibration compensates temperature and humidity drifts in the supplied air resulting in accurate, reliable and stable measurement results over a long period of time.

Optional integrated Dew Point Sensor

To ensure compressed air quality and purity, further from oil vapor monitoring, dew point measurement is an essential key parameter. Therefore, we offer an optional integrated Dew Point Sensor (-100 … +20 °C Td) to measure both parameters in one compact device with an excellent price performance ratio

SUTO Exchange Service

The exchange calibration service eliminates downtime and enables users to have a seamless record of their oil vapor monitoring. Please find more information here.

If you need advice for the use in your application or if you have further questions, please contact us here. We are happy to find the best possible solution for you.

Permanent monitoring of oil content in compressed air and gas systems to ensure crucial processes in:

- Medical air

- Pharmaceuticals

- Food and beverage

- Semiconductor fabs

- High-tech applications

MESSUNG | |

| Oil Vapor | |

| Measuring range | 0.001 ... 5.000 mg/m³ (Based on 1000 hPa(a), 20 °C, 0 % relative humidity) |

| Accuracy | 5 % of reading ± 0.003 mg/m³ |

| Resolution | 0.001 mg/m³ |

| Selectable units | mg/m³ / ppm |

| Sensor principle | Photo ionization detector |

| Pressure | |

| Measuring range | 0 ... 16 bar(g) |

| Accuracy | 0.5 % FS |

| Resolution | 0.01 bar(g) / 0.001 MPa / 0.1 psi |

| Selectable units | bar(g) (default), MPa and psi (on request) |

| Sensor principle | Piezo resistive pressure sensor |

| Dew Point (optional) | |

| Measuring range | -100 ... +20 °C Td |

| Accuracy | ±1 °C Td (0 ... 20 °C Td) ±2 °C Td (-70 ... 0 °C Td) ±3 °C Td (-100 ... -60 °C Td) |

| Resolution | 0,1 °C Td |

| Selectable units | °C Td / °F Td |

| Sensor principle | QCM + Polymer |

| Temperature | |

| Measuring range | 0 ... 50 °C |

| Accuracy | 0.5 °C |

| Resolution | 0.1 °C |

| Selectable units | °C / °F |

| Sensor principle | NTC |

SIGNAL INTERFACE & SUPPLY | |

| Outputs / Interface | |

| Analogue output | 4 ... 20 mA, isolated |

| Alarm output | Relay, NO, 40 VDC,0.2A |

| Digitale Schnittstelle | Modbus/RTU (RS485) Modbus/TCP (Ethernet) & USB (only available for display version) |

| Display (optional) | 5” color touch screen with a data logger of 30 million measurement values |

| Supply | |

| Power supply | 24 VDC ± 5 %, 10 W |

GENERAL DATA | |

| Measuring medium | Compressed air, N2, CO2 (for other gases please contact us) |

| Sample flow rate | < 2 l/min, measuring gas is released to ambient |

| Sample rate | 1/sec |

| Gas / Operating temperature | -20 ... +50 °C |

| Transport temperature | -30 ... +70 °C |

| Operating pressure | 3 ... 15 bar(g) 0.5 ... 2 bar(g) (optional) 0.60 ... 1.07 bar(a) (ambient version only) |

| Gas humidity | < 40 % rel. humidity, no condensation |

| Gas connection | 6 mm quick connect |

| UV lamp lifetime | 6,000 working hours or 1 year, whichever comes first |

| Electrical connection | M12, USB, RJ45 |

| Settings | Various sensor settings can be performed through SUTO display units or through the related service software |

| Housing material | PC, Al alloy |

| Protection class | IP65 |

| Dimensions | 271 x 231 x 91 mm |

| Weight | 2.4 kg |

| Approval | CE |

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We’re here to help!