S415

S415 Compact Flow Meter for Compressed Air and Nitrogen (Eco-Inline)

Reliable and highly economical compressed air flow and consumption measurement directly at the point of use.

Compact flow meter for installation at the point-of use

Economic flow and consumption metering at low investments

Flow conditioner eliminates need of straight inlet

Mobile App for remote configuration and online values

Total Mass Flow: No bypass measurement required

Compact design makes it easy and flexible to install

Isolated 4... 20 mA & Pulse; Modbus/ RTU; M-Bus

G inner thread connection: DN8, DN15, DN20, DN25 or DN32

The SUTO S415 Compact Flow Meter offers compressed air flow and consumption measurements directly at the point of use. It is designed to be seamlessly integrated into your compressed air system or in nitrogen gas applications.

Optimize Your Compressed Air and Nitrogen Systems

This highly economical flow meter will help you improve compressed air system efficiency, while helping reduce compressed air usage and operating costs. The S415 comes standard with a wireless communication interface to help the user quickly and easily check the flow meter readings or adjust the settings via the free SUTO flow meter app S4C-FS.

Various Sensor Outputs

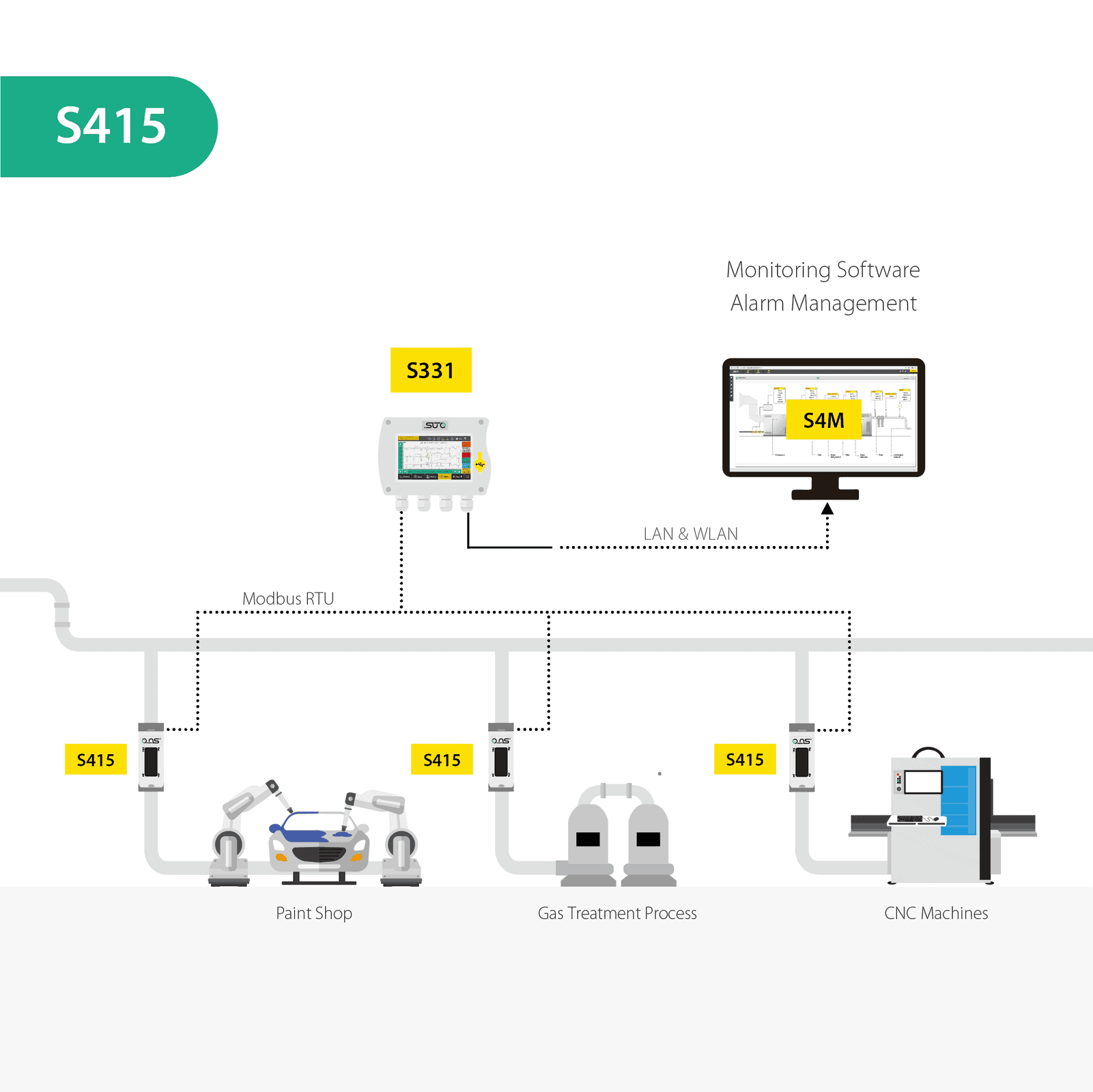

The S415 provides various sensor outputs, such as 4 … 20 mA, Modbus/RTU and M-Bus. With the Modbus/ RTU interface, the S415 can be easily daisy-chained to a Modbus Master device such as our SUTO S331 Data Logger by using an RS-485 splitter (A554 3310) and the M8 to M12 converter cable (A553 0161). Through this method, you can add up to 16 flow meters to a single master device, making it versatile for bigger monitoring systems.

Integrated Flow Conditioner

With a highly engineered flow conditioner, there is no additional straight inlet piping needed. The innovative mechanical design reduces the pressure loss to a minimum (<30 hPa). This guarantees highly accurate measurement in difficult pipeline designs.

Low-Cost and Broad Monitoring

The S415 flow meter is best suited to general process work where low-cost and broad monitoring of compressed air and nitrogen flow are required. Easily monitor the compressed air flow and consumption of individual machines and processes to improve efficiency and reliability.

Mobile configuration and real-time data

Various settings, such as gas type, flow unit, and reference standards, can be set in the factory according to your needs. If settings need to be changed on site, they can be done using the free S4C-FS smartphone application. This enables users to change the settings of the flow sensor wirelessly on site. Flow meter settings are well protected from unwanted access with the use of a unique QR access code for each meter. Should you have any special requests, such as custom flow ranges or different gas types, please contact us here?

- Compressed air and gas flow and consumption measurement at point of use

- Monitoring of operation costs and consumption of machines and compressed air users

MEASUREMENT | |

| Flow | |

| Accuracy | 3 % o.RDG ±0.3 % FS |

| Selectable units | l/min, cfm, kg/h, m3/h |

| Measuring range | see table on the previous page |

| Repeatability | 1 % o.RDG |

| Sensor | Thermal mass flow sensor |

| Sampling rate | 3/sec |

| Turndown ratio | 50:1 |

| Response time (t90) | 2 sec |

| Consumption | |

| Selectable units | m³, ft3, l, kg |

| Reference conditions | |

| Selectable conditions | 20 °C 1000 mbar (ISO1217) 0 °C 1013 mbar (DIN1343) freely adjustable |

SIGNAL INTERFACE & SUPPLY | |

| Analog output | |

| Signal | 4 ... 20 mA, isolated |

| Scaling | 0 ... max flow |

| Load | 250R |

| Update rate | 3/sec |

| Pulse output | |

| Signal | Max 30 V, 200 mA |

| Scaling | 1 pulse per consumption unit |

| Fieldbus | |

| Interface/Protocol | RS-485/Modbus/RTU M-Bus |

| Supply | |

| Voltage supply | 15 ... 30 VDC |

| Current consumption | 120 mA @ 24 VDC |

GENERAL DATA | |

| Configuration | |

| Wireless | S4C-FS App for mobile phones |

| Display | |

| Integrated | 4 digit LED |

| Material | |

| Process connection | Aluminum alloy |

| Housing | PC + ABS |

| Sensor | Glass coated resistive sensor |

| Metal parts | Aluminum alloy |

| Miscellaneous | |

| Electrical connection | 2 x M8 (4 pole) |

| Protection class | IP54 |

| Approvals | CE, RoHS, FCC |

| Process connection | G-thread |

| Weight | 0.45 ... 1.3 kg (depends on model) |

| Operating conditions | |

| Medium | Air, N2 |

| Medium quality | ISO 8573: 4.4.3 or better |

| Medium temperature | 0 ... 50 °C |

| Medium humidity | < 90 % rH, no condensation |

| Operating pressure | 0 ... 10 bar(g) |

| Ambient temperature | 0 ... 50 °C |

| Ambient humidity | < 95 % rH |

| Storage temperature | -30 ... 70 °C |

| Transport temperature | -30 ... 70 °C |

| Pipe sizes | DN8, DN15, DN20, DN25, DN32 |

MEASUREMENT RANGE IN AIR (L/MIN) | |||||

| Process connection | DN8 | DN15 | DN20 | DN25 | DN32 |

| Standard range (S) | 250 | 1000 | 2000 | 3500 | 6000 |

| Low range (L) | 50 | 200 | 400 | 700 | 1200 |

| Stated measuring ranges for S415 under following conditions: Standard flow in air in l/min Reference pressure: 1000 mbar Reference Temperature: +20 °C |

|||||

| Measuring ranges in Nitrogen are different. Please contact us for details at [email protected] | |||||

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We’re here to help!