LEAK DETECTION FOR COMPRESSED AIR AND GASES

Leaks are the leading cause of wastage of a significant part of electric energy in the compressed air leak detection systems, which cause an energy loss of about 15 – 20 percent every year. Therefore, finding, monitoring, and fixing up the leaks present in a compressed air system is essential in becoming a better energy-efficient compressed air consumer.

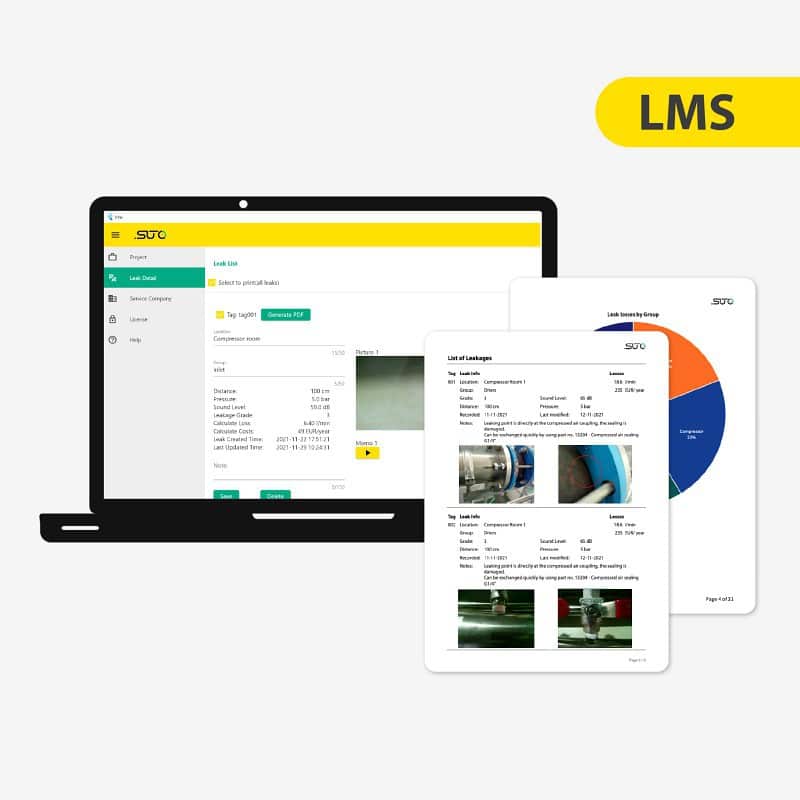

SUTO iTEC offers ultrasonic leak detectors for compressed air and gaases that are easy to use and an easy-to-operate cloud-based software system to monitor leaks and offer audit reports for better energy management.

THE IMPORTANCE OF COMPRESSED AIR LEAK DETECTION

So, the leakages are a vital factor to cause the electric energy loss in industrial and domestic compressed air systems. This wastage can sometimes account for about twenty to thirty percent of the total output of the compressor. Also, these leakages in a compact air system can cause other specific issues such as the pressure drop in the design and compel the compressor to keep running for a longer than required time.

A conventional way of leakage detection in these compressed air or other gas systems is spraying the pipes with soapy water and then detect the leakages with the help of the bubbles formed due to the soapy water. However, this old practice is not functional in today’s era of advanced technology due to its time-consuming operation and less efficiency of leakage detection.

In the following, we have collected all the important information about leak detection in compressed air systems.

Where can leakages occur?

Uncanny leaks are the most common maintenance issues that can appear in any part of the system. Such kinds of leaks require proper detection of the location of the leak and a repair. Although leakage can occur in any part of the system, generally, the most common problem areas are:

- Fittings, tubes, hoses, and couplings: Push-to-lock and tubes are among various typical problems.

- Open condensate traps: Improperly operating dirty seals and solenoids are often major problem areas.

- Regulators, lubricators, and filters: Improper installation can also cause such leakage.

- Disconnects: Maybe O-rings are missing to complete the sealing.

- Shut-off and control valves: Worn packing of the stem can also cause leakage.

- Point-of-use devices: Poorly maintained or old tools can have several internal leaks.

- Thread sealants: Improperly applied or incorrect thread sealants can result in leaks.

- Flanges: Missing welds are among common problems. Consider using the highest quality materials, besides applying them according to the instructions.

- Pipe joints: If welds are missing, they can also trigger this kind of leakage.

- Cylinder rod packing: If packing materials are worn out, they can cause leakage.

Why ultrasonic detectors for leakage detection?

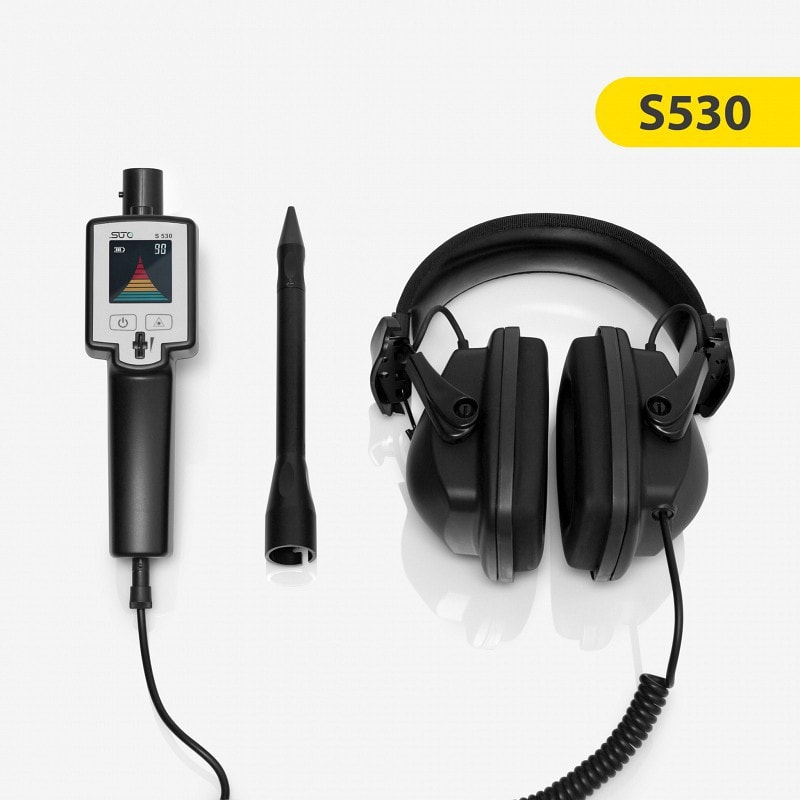

Since air leakages are nearly invisible, we devise other ways to see them. The best method to find leakages is to use an ultrasonic leakage detector for compressed air and gases, which can sense the high-frequency sounds of the compressed air leakages.

These portable devices include directional microphones, audio filters, and amplifiers, and most have either earphones or visual indicators to detect leakages. Ultrasonic leakage detection is nowadays the most predominant form of leakage detection. Due to its efficient build-up, it adapts to several leakage detection situations.

The principle of this leak detection is more than superficial. The leak moves from a high-pressure laminar flow towards low-pressure turbulence in a vacuum or pressure leak. This disturbance causes a noise that usually has inaudible frequencies that human ears cannot detect. The ultrasonic leakage detector converts these inaudible noise signals to audible ones while ignoring the loud background noise with the help of audio filters. So, you can hear leakages with the use of wireless headsets even in the noisiest places.

SUTO iTEC’s Compressed Air Leak Detectors are equipped with ultrasonic technology, providing an advanced and precise solution for detecting and addressing leaks in compressed air systems. Talk to our experts for more information.

What are the advantages of ultrasonic leak detection?

The benefits of ultrasonic leak detection include speed, versatility, and ease of use. Moreover, it provides the ability to find a wide variety of leakages to perform tests while equipment is running. They need a minimum of training, and operators mostly become competent after only 15 minutes of activity.

Because of the nature of ultrasound, it is directional in transmission. Due to this reason, signals are loudest near the source. By scanning the test area, it is straightforward to pinpoint the exact location. Hence, it is a very accurate and fast process.

How does compressed air leak detection improve overall performance?

Compressed air leak detection improves overall system performance by identifying and repairing leaks that can affect efficiency and productivity. SUTO iTEC’s expertise ensures accurate detection, helping to maintain optimal performance and extend the life of your compressed air system. Our advanced compressed air leak detection solutions will improve your operational reliability.

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We will be happy to help you!