S462

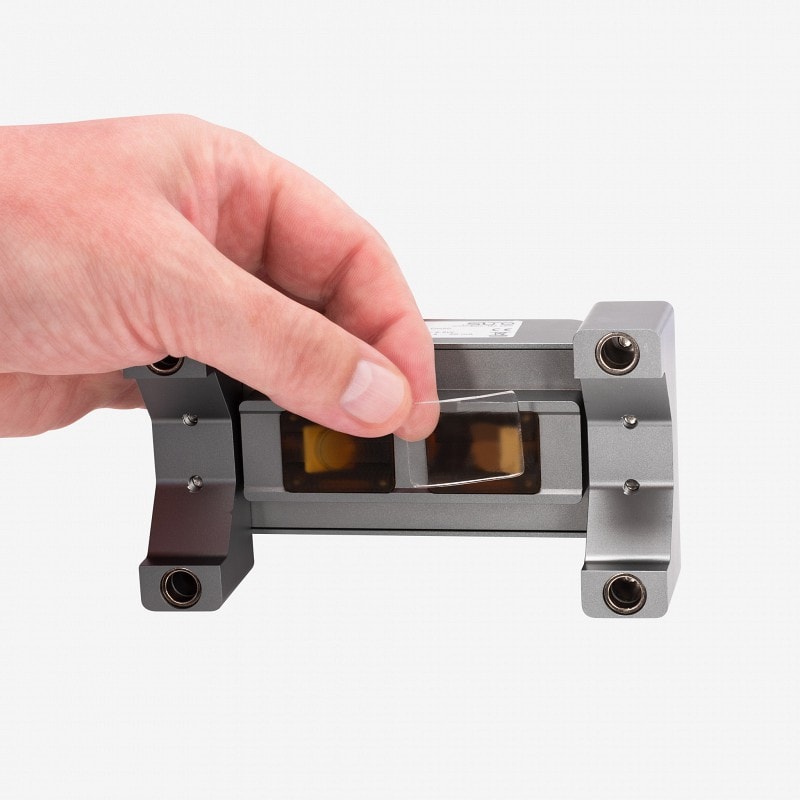

S462 Compact Ultrasonic Flow Sensor for Water and other Liquids (Clamp-On)

Accurate flow measurement of water and other liquids with easy installation, no pressure loss or leakage.

Easy to use liquid flow measurement solution

Used as portable solution connected to S551 data logger

Used as stationary solution connected to S330 / S331

Fast installation anywhere thanks to compact design

No contact with the medium thanks to clamp on technology

Transit Time Correlation Technique

Installation on many different pipe materials

Clamp-on installation for pipe sizes of DN20 ... DN40

The SUTO S462 Clamp-On Ultrasonic Flow Sensor for Water and Other Liquids offers our users a highly economical and easy to install liquid measurement solution. The Flow Sensor is available for pipe sizes from DN20 to DN40. The S462 provides accurate liquid flow and consumption measurement without causing process downtime, pressure loss or contamination of the medium to be measured.

Installation in a Few Minutes

The S462 can be installed in just a few minutes using clamp-on technology. The compact design allows the user to install the sensor even where space is limited.

Various Output Options

The S461 Water Flow Sensor connects to any monitoring system through analog output and/or Modbus/RTU interface. The S462 is also compatible with the displays and data loggers S331 and S551 from SUTO.

OLED Display

Equipped with an OLED display and a keyboard, parameter settings are easily done on the spot. Setting changes can be locked to prevent unwanted modifications. The display direction can be reversed to make it readable in any installation direction.

S462 holds statistics of daily, weekly and monthly consumption over a long period of time, that can be retrieved through the local display or the interface.

Please contact us here for more information. We are happy to help.

Clean fluid measurements in:

- Cooling / Heating / Process Water

- Purified Water Measurement

- Fuel, Oils, Petroleum Products

- Water Treatment

- Food / Beverage

- HVAC / Energy System Audits

- Sanitary flow metering

- Hydraulic System Test

- Pharmaceutical Industry

MEASUREMENT | |

| Flow | |

| Accuracy | 1.5 % o.RDG + 0.2 % FS (0.5 ... 5.0 m/s) |

| Selectable units | m³/h, l/min, GAL |

| Measuring range | see table below |

| Repeatability | 0.80 % o.RDG |

| Sensor | Piezo ultrasonic transducer |

| Sampling rate | 3 samples / sec |

| Turndown ratio | 10:1 |

| Response time (t90) | <2 sec |

| Consumption | |

| Selectable units | m³, Liter, GAL |

| Reference conditions | |

| Selectable conditions | 20 °C 1000 mbar (ISO1217), 0 °C 1013 mbar (DIN1343) freely adjustable |

SIGNAL INTERFACE & SUPPLY | |

| Analog output | |

| Signal | 4 ... 20 mA |

| Scaling | 0 ... max flow / adjustable |

| Load | <600R |

| Update rate | 3/sec |

| Fieldbus | |

| Protocol | Modbus/RTU |

| Supply | |

| Voltage supply | 20 ... 28 VDC |

| Current consumption | 100 mA @ 24 VDC |

GENERAL DATA | |

| Configuration | |

| Settings | via integrated keyboard |

| Display | |

| Integrated | OLED, 128 x 64 pixel (31 x 16 mm) |

| Data Logger | |

| Totalizer | Daily, monthly, yearly consumption |

| Material | |

| Housing | Aluminum alloy |

| Sensor | PEI |

| Display cover | PMMA |

| Key pad | F150 |

| Miscellaneous | |

| Dimensions | see dimension drawing |

| Electrical connection | 1 x M12 (5 pole) |

| Protection class | IP65 |

| Approvals | CE, RoHS, FCC |

| Weight | 0.47 ... 0.60 kg (depends on model) |

| Operating conditions | |

| Medium | Water, sea water, others on request |

| Medium quality | No solid particles, no air bubbles |

| Pipe material | Carbon steel, stainless steel, copper, PVC, PP, PU |

| Medium temperature | 0 ... 50 °C |

| Ambient temperature | 0 ... 50 °C |

| Ambient humidity | < 95 % rH |

| Storage temperature | -30 ... +70 °C |

| Transport temperature | -30 ... +70 °C |

| Pipe sizes | DN20, DN25, DN32, DN40 |

Personal advice

Would you like to receive more information about products and applications?

Or do you need personal advice? We’re here to help!